Material Property Influence on Efficacy of E-Jet Printing

Student: Angelo Hawa, Ali Bahrami

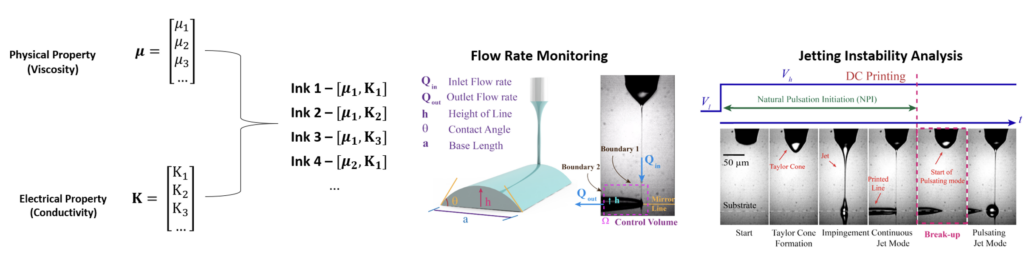

In order to define the efficacy of e-jet printing across applications, ink material property constraints for stable printing must be analyzed. While a list of influential material properties has been identified (surface tension, conductivity, viscosity, etc.), the effect on printing dynamics is not well understood. This research project examines the influence of varying ink material properties on the feasibility, repeatability, and controllability of e-jet printing while defining the voltage input constraints for stability. Current progress includes the development of preliminary results and trends regarding the ink viscosity and conductivity on the prevalence of unstable printing behavior. Flow rate monitoring techniques have been implemented to analyze the cause of the behavior.

Developing a Data Analysis Pipeline to Characterize Input/Output Relationships in Material Jetting

Student: Angelo Hawa

Defining an optimal input signal requires prior knowledge of input/output relationships in the jetting process. This research project combines high-speed imaging data collection with computer vision analysis techniques to define process parameter relationships in e-jet printing. Machine learning is implemented to predict and evaluate relevant temporal and volumetric constants, such as flow rate, jet impingement time, and jet relaxation time. Current progress includes the development of computer vision algorithms to analyze jetting behavior, in addition to the preliminary identification of process parameter relationships.

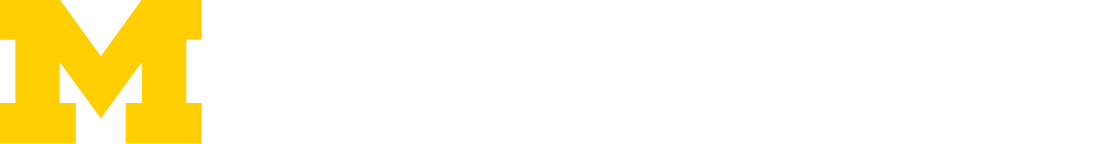

Manufacturing Autonomy For High-resolution And Conduction Interconnect Using Electrohydrodynamic Jet Printing

Student: Kaifan Yue

This research focuses on fabricating electrical interconnect for nano-scale electrical components using electrohydrodynamic jet printing. Initial objectives include the development of sensing capabilities at sub-micron scale, identification of process strategies that enables submicron printed interconnects, and derivation of models that characterize the interconnects’ dimensions and electrical performance. The developed printing system will be extended to an intelligent interconnect manufacturing autonomy that integrates circuit layout identification, route planning, and motion control for the fabrication of high-performance integrated circuits.

High-fidelity simulation of electrohydrodynamic jet (e-jet) printing

Student: Ali Bahrami

This research aims to develop high-fidelity Computational Fluid Dynamics (CFD) models for e-jet printing in order to design more robust controllers. E-jet printing involves complex multi-phase flow that exhibits different modalities under varying inputs. We use a leaky dielectric model, along with multiphase solvers, to solve the hydrodynamic and electrostatic equations that govern e-jet printing. This project aims to develop and validate CFD models for the different modalities of e-jet printing. Achieving this objective will enable the use of CFD to design optimal e-jet operational parameters and reduce the need for costly experiments in studying e-jet printing.

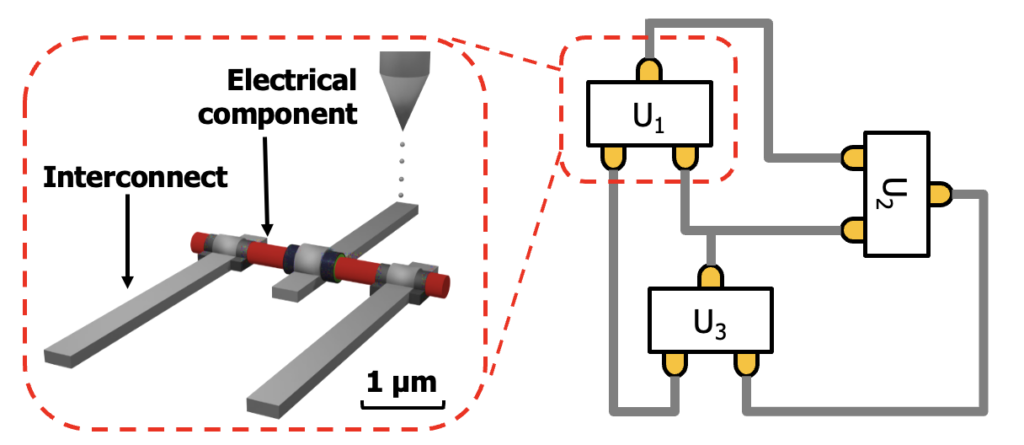

Predictive Health Monitoring of Commercial 3D Printers Leveraging Digital Twin Technology

Student: Hongrui Liu

This project aims to establish a predictive health monitoring (PHM) framework to enable real-time process and part monitoring of a commercial 3D printer towards part/process anomaly detection, predictive process behavior, and optimized process performance. Herein, suitable process parameters (e.g., extrusion rate, print speed, substrate temperature) and performance metrics to effectively evaluate the proposed framework will be identified based on experimental testing and real-time assessment of the PHM performance.