Production as a Service (PaaS)

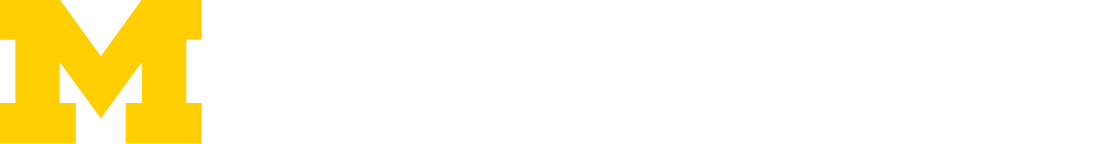

In this research, we present a cloud-based digital manufacturing framework, Production as a Service (PaaS), to connect users who have small batch customized manufacturing needs, with manufacturers that have existing underutilized resources. PaaS abstracts a user’s production request to a predefined ontology and collects production quotes from the manufacturers to run a customizable optimization algorithm. Solutions resulting from the optimization algorithm present a set of feasible and optimal production schemes to the user.

Software-Defined Control for Smart Manufacturing

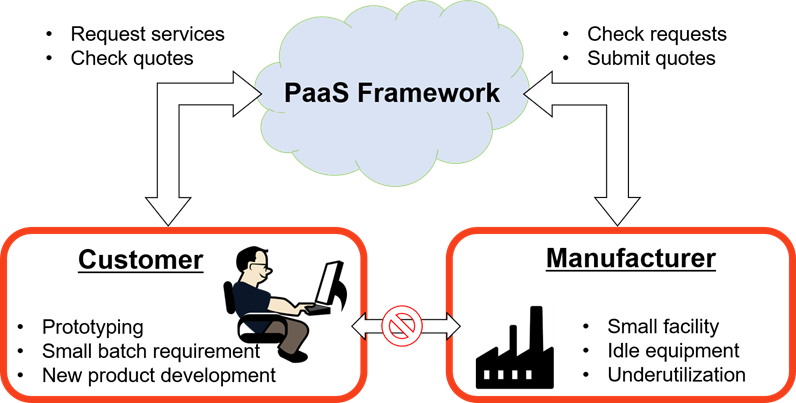

Software-defined control (SDC) is a framework for the rapid reconfiguration of smart manufacturing systems in response to changing demands or factory conditions, supply networks, or customer needs. SDC abstracts the low-level functionality of the factory floor in a control plane that hosts a central controller. A set of applications (e.g., anomaly detection, quality control) provide the central controller with the necessary information to detect changes in the system, evaluate alternative configurations, and make recommendations for reconfiguration that can be rapidly deployed to the factory floor. Compared to other reconfiguration frameworks, SDC provides advantages in flexibility, compatibility with prevailing automation technologies, and the ability to monitor system performance. Since the manufacturing system is allowed to function with or without the central controller, SDC is strictly value-add and it may be turned off if reconfiguration is not desired. Modeling and Control for Manufacturing Intelligence

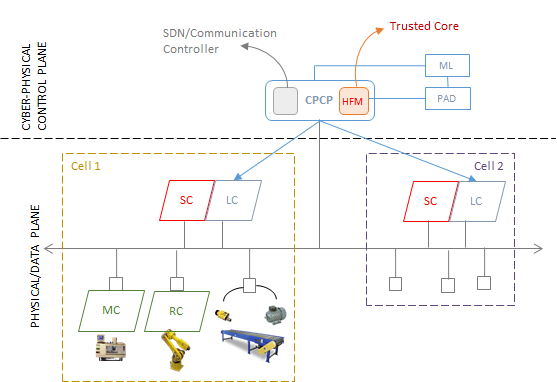

The goal of this project is to optimize the productivity of manufacturing systems while considering maintenance of the equipment and energy usage. To accomplish this goal, we will develop modular hybrid models of the different components in the manufacturing system. Taking advantage of a large amount of operational data that is being produced and pushed to the Cloud, we will develop automatic methods to extract the parameters for these models from real-time data streams. Data from both Cyber and Physical domains will be used to develop an anomaly detection framework. Finally, we will develop optimization functions that can encode the tradeoffs between productivity, energy usage, and reliability to solve for the optimal machine parameters in order to improve system performance

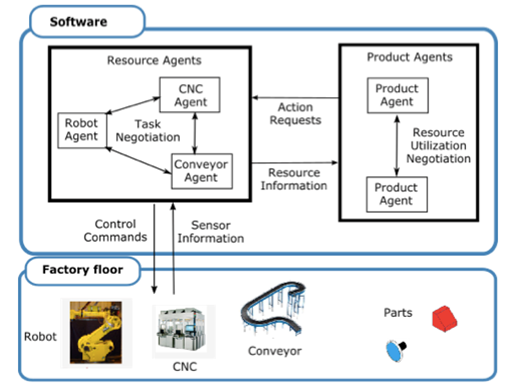

Multi-Agent Control for Manufacturing Systems

Present-day manufacturing companies encounter a variety of challenges due to the dynamically changing industrial environment. Current control frameworks lack the adaptability and flexibility to effectively deal with challenges such as broken down machines or altered customer orders. One type of strategy that can be utilized to address these challenges is multi-agent control of manufacturing systems. The multi-agent control strategy consists of a number of agents working together to achieve individual objectives based on their local environment. These agents represent various types of physical (e.g. robot, part, mill, etc.) or cyber (e.g. work order) components present in an industrial environment. By utilizing local information and relying on local interactions, multi-agent control can improve the flexibility and reactivity of manufacturing systems during unexpected events.

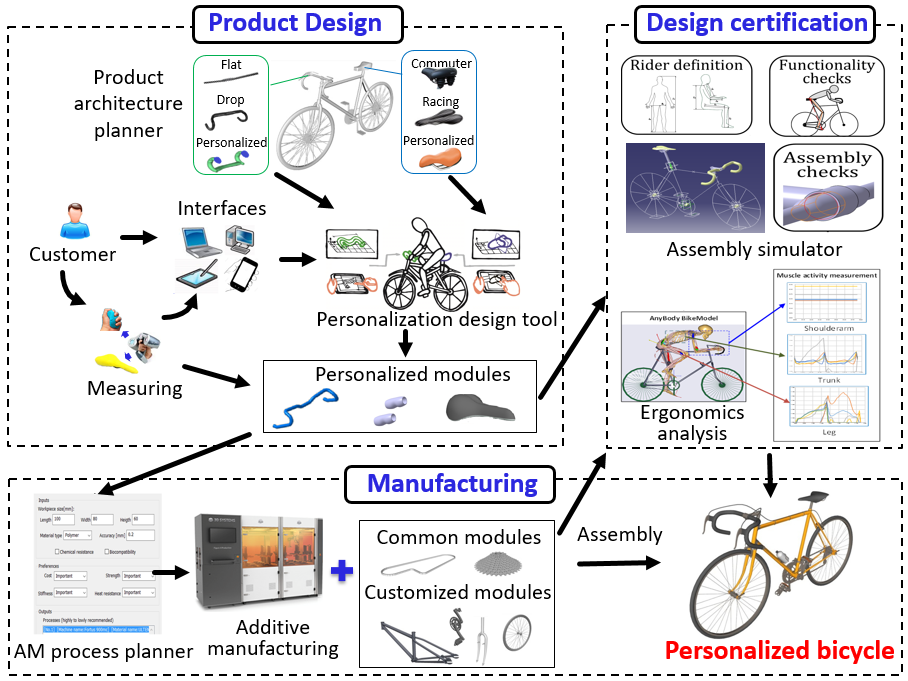

Cyber-Manufacturing Systems for Open Product Realization

Open product realization (OPR) is a new manufacturing paradigm. OPR will allow customer to personalize certain product modules, and integrate personalized modules into a product architecture with other manufacturer-created common and customized modules to build a unique product to meet individual needs. By integrating three types of modules, products made by OPR can possess the quality and cost characteristics of mass production, high variety as achieved in mass customization, and efficacy by allowing personalization. Open product realization is ambitious yet realistic. It is enabled by open product architecture, responsive manufacturing technologies, and a powerful cyber system empowering customer participation in product “co-creation”. This project aims to develop scientific principles and methods for designing cyber manufacturing systems in support of OPR involving user-in-the-loop design, responsive manufacturing, and distributed assembly. Major research tasks include product architecture design incorporating customer preferences based on conjoint analysis, cyber platform supporting product co-design, cyber tool of virtual product assembly simulation, and on-demand manufacturing process planning.